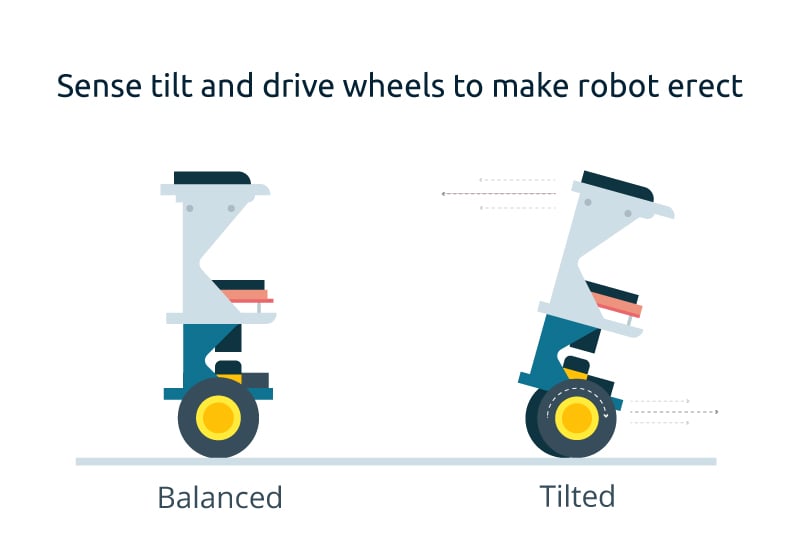

The segway tries to get the angle down to 0°. If the angle is positive, the segway brakes or accelerates backwards. If it's negative the segway accelerates forward.

But which signal get the motors? This is exactly the task of the pid-Controller.

Now it's time to start the segway. To drive not only straight ahead you have to mount two buttons. When you push f.e. the right one, the left Motor increases Speed and the right Motor slows down. To ensure smooth transitions the added and deducted value starts at zero and increases step by step (+0.5 every loop) until he reaches the maximum value (f.e. 30).

To try out your own segway I 've attached the simple program for you. Good luck and don't follow the segway-inventor James Heselden down a cliff ;-)

// -------------------------------------------------------------------------------------------------------------------------------------------------------------------------

// ------------ Programm zur Berechnung des Neigungswinkels aus den Gyro- und Beschleunigungsdaten unter Verwendung eines Kalman-Filters ----------------------------------

// -------------------------- und PID-Regelung zur seriellen Ansteuerung der beiden Motoren mittels Sabertooth-Motortreiber -----------------------------------------------

// -------------------------------------------------------------------------------------------------------------------------------------------------------------------------

#include "Wire.h"

#include "I2Cdev.h" // I2Cdev and MPU6050 must be installed as libraries

#include "MPU6050.h" // class default I2C address is 0x68 = AD0 low

#include <math.h>

#include <SoftwareSerial.h>

#include <SabertoothSimplified.h>

SoftwareSerial SWSerial(NOT_A_PIN, 11); // RX on no pin (unused), TX on pin 11 (to S1).

SabertoothSimplified ST(SWSerial); // Use SWSerial as the serial port.

MPU6050 accelgyro;

int16_t ax, ay, az; // Beschleunigungswerte in x-,y- und z-Richtung des MPU6050-Sensors

int16_t gx, gy, gz; // Winkelgeschwindigkeitswerte in x-,y- und z-Richtung des MPU6050-Sensors

#define Pin_Lenkung_rechts 12 // Pin-Anschluss für den Lenkbefehl Rechts

#define Pin_Lenkung_links 13 // Pin-Anschluss für den Lenkbefehl Links

#define Pin_Schalter_Box 3 // Pin-Anschluss des Box-Schalters, um zwischen Motorsynchronisation und I-Regelung zu wählen

#define Pin_PID_Regelung_P A1 // Pin-Anschluss für das Poti zur Veränderung des P-Anteils

#define Pin_PID_Regelung_I A2 // Pin-Anschluss für das Poti zur Veränderung des I-Anteils

#define Pin_PID_Regelung_D A3 // Pin-Anschluss für das Poti zur Veränderung des D-Anteils

int LoopTime_Soll = 9; // gewünschte Schleifendauer in ms um auf die 100 Hz zu gelangen

int LoopTime_Angepasst = LoopTime_Soll; // letzte Schleifenzeit mit erzwungener Pause

int LoopTime_Bisher = LoopTime_Soll; // letzte Schleifenzeit ohne erzwungener Pause

unsigned long LoopTime_Start = 0; // Startzeit der Schleife

float Winkel; // aktueller Neigungswinkel

float Winkel_Soll; // Sollwert des Neigungswinkels, also 0°

float Winkel_Grenze; // maximal erlaubter Neigungswinkel, über dem das Segway abgeschaltet wird

float ACC_angle; // Winkel vom Beschleunigungssensor

float GYRO_rate; // Winkelgeschwindigkeit vom Gyro-Sensor

float Kp,Ki,Kd,K; // Konstanten zur PID-Regelung, Differentteil, Integralteil, Differentialteil, Gesamtanteil

int Motor; // von der PID-Regelung erhaltener Wert zur Motoransteuerung

int Motor_rechts, Motor_links; // Werte für die beiden Motoren

float K_Motor_links, K_Motor_rechts; // Korrekturfaktoren für einen synchronen Lauf der beiden Motoren

int Schalter_Box; // Variable, welche die Schalterstellung an der Box abfragt

int Lenkung_Eingang_rechts = 0; // Variable zum Erfassen eines Lenkbefehls nach Rechts

int Lenkung_Eingang_links = 0; // Variable zum Erfassen eines Lenkbefehls nach Links

float Lenkung_max; // Wert, um den sich die Motoransteuerung bei einem Lenkbefehl maximal ändern soll

float Lenkung_rechts, Lenkung_links; // aktueller und schrittweise erhöhter Ansteuerungswert beim Lenken nach rechts bzw. links

// ****************************************************************************

// ****************************** SETUP ***************************************

// ****************************************************************************

void setup()

{

Wire.begin();

//SWSerial.begin(9600); // This is the baud rate you chose with the DIP switches.

Serial.begin(9600); // baud rate für den seriellen Monitor, um die Werte zu überprüfen

// initialize device

accelgyro.initialize();

calibrateSensors(); // Unterprogramm zum einmaligen Kalibrieren der Sensoren

}

// ***********************************************************************************

// ****************************** Kalibrierung ***************************************

// ***********************************************************************************

void calibrateSensors() // einmalige Ermittlung der Sensor-Nullwerte (Mittelwert aus jeweils 50 Messungen)

{

// =================================================

// ======== Änderung der Sensor-Auflösung ==========

// =================================================

// ===========================================================================

// read raw accel/gyro measurements from device

// Ausgabewerte-Acc: Auflösung 2g: 16384/g Auflösung 4g: 8192/g

// Ausgabewerte-Gyro: Auflösung 250°/s: 131/°/s Auflösung 500°/s: 65.5/°/s

// ===========================================================================

accelgyro.setFullScaleAccelRange(MPU6050_ACCEL_FS_2);

accelgyro.setFullScaleGyroRange(MPU6050_GYRO_FS_500);

// Versuch, das "Aufheulen" der beiden Motoren zu Beginn zu vermeiden

ST.motor(1, 0);

ST.motor(2, 0);

Winkel_Soll = 0.0; // Sollwert für den Neigungswinkel

Winkel_Grenze = 30.0; // maximal erlaubter Neigungswinkel

// *******************************************************

// ********** K - Werte für die PID-Regelung *************

// *******************************************************

Kp = analogRead(Pin_PID_Regelung_P) * 25.0 / 1023.0; // Differenzenanteil mit Poti festgelegt

Ki = 0.1; // Integralanteil mit Poti festgelegt (Schalter aber womöglich auf Motorkorrektur, daher mit 0.1 zunächst festgesetzt)

Kd = analogRead(Pin_PID_Regelung_D) * 100.0 / 1023.0; // Differentialanteil mit Poti festgelegt

K = 1.0; // Gesamtanteil

// **************************************************

// ********** K - Werte für die Motoren *************

// **************************************************

pinMode(Pin_Schalter_Box, INPUT); // Pin für die Auswahl zwischen I-Regelung und Motorsynchronisation

K_Motor_rechts = 1.0; // Korrekturfaktor für den rechten Motor

K_Motor_links = 0.8; // Korrekturfaktor für den linken Motor

// **********************************************

// ********** Werte für die Lenkung *************

// **********************************************

Lenkung_max = 25.0; // Wert, um den sich die Motoransteuerung bei einem Lenkbefehl MAXIMAL ändern soll

Lenkung_rechts = 0.0; // aktueller Zusatzwert beim Lenkvorgang nach rechts

Lenkung_links = 0.0; // aktueller Zusatzwert beim Lenkvorgang nach links

pinMode(Pin_Lenkung_rechts, INPUT); // Pin für Lenkung nach Rechts wird als Input deklariert

pinMode(Pin_Lenkung_links, INPUT); // Pin für Lenkung nach Links wird als Input deklariert

}

// ***************************************************************************************************************************************************

// ***************************************************************************************************************************************************

// ********************************************************************** HAUPTSCHLEIFE **************************************************************

// ***************************************************************************************************************************************************

// ***************************************************************************************************************************************************

void loop()

{

// *******************************************************

// ********************* Sensorabfrage *******************

// *******************************************************

// ===========================================================================

// read raw accel/gyro measurements from device

// Ausgabewerte-Acc: Auflösung 2g: 16384/g Auflösung 4g: 8192/g

// Ausgabewerte-Gyro: Auflösung 250°/s: 131/°/s Auflösung 500°/s: 65.5/°/s

// ===========================================================================

accelgyro.getMotion6(&ax, &ay, &az, &gx, &gy, &gz);

ACC_angle = atan(ay * 1.0 / az * 1.0) * 180.0 / 3.141592654; // Auflösung 2g: 16384/g

//ACC_angle = atan((ay/16384.0) / (az/16384.0)) * 180.0 / 3.141592654; // Auflösung 2g: 16384/g

GYRO_rate = gx/65.5; // Auflösung 500°/s: 65.5/°/s

// *******************************************************

// ********** K - Werte für die PID-Regelung *************

// *******************************************************

Kp = analogRead(Pin_PID_Regelung_P) * 25.0 / 1023.0; // Differenzenanteil mit Poti festgelegt; Maximum = 25

Kd = analogRead(Pin_PID_Regelung_D) * 100.0 / 1023.0; // Differentialanteil mit Poti festgelegt; Maximum = 100

Schalter_Box = digitalRead(Pin_Schalter_Box); // Abfrage des Pins für den Schalterzustand an der Box

if (Schalter_Box == HIGH) // Mittels Schalter an der Box I-Regelung aktiviert

{

Ki = analogRead(Pin_PID_Regelung_I) * 2.0 / 1023.0; // Integralanteil mit Poti festgelegt; Maximum = 2

}

else // Mittels Schalter an der Box Motor-Regelung aktiviert

{

K_Motor_rechts = analogRead(Pin_PID_Regelung_I) * 2.0 / 1023.0; // Korrekturfaktor für einen synchronen Lauf der beiden Motoren; Maximum = 2

}

// ********************************************************************************

// ****************** Kalmanfilter, PWM-Berechnung und Motorwerte *****************

// ********************************************************************************

Winkel = kalmanCalculate(ACC_angle, GYRO_rate, LoopTime_Angepasst); // mit Kalmanfilter berechneter Winkel

if (Winkel > Winkel_Grenze || Winkel < (Winkel_Grenze * (-1)))

{

// ===============================================

// Abbruch aufgrund des zu großen Neigungswinkels!

// ===============================================

ST.motor(1, 0);

ST.motor(2, 0);

}

else

{

// =========================

// Neigungswinkel in Ordnung

// =========================

Motor = pid(Winkel, Winkel_Soll, GYRO_rate); // Berechnung des PWM-Werts zur Ansteuerung der Motoren

Motor_rechts = K_Motor_rechts * Motor; // Berechnung der mittels K-Faktor synchronisierten Motordrehzahl für den rechten Motor

Motor_links = K_Motor_links * Motor; // Berechnung der mittels K-Faktor synchronisierten Motordrehzahl für den linken Motor

// **************************************************************************************

// ***** Abfrage ob die Lenkung betätigt wurde und Veränderung der Motoransteuerung *****

// **************************************************************************************

Lenkung_Eingang_rechts = digitalRead(Pin_Lenkung_rechts); // Abfrage des Pins für Lenkung nach Rechts

if (Lenkung_Eingang_rechts == HIGH)

{

// ******************************************

// *** Lenkung nach Rechts wurde gedrückt ***

// ******************************************

if (Motor_rechts >= 0) // segway fährt gerade vorwärts oder steht. Welcher Motor abgefragt wird, ist egal.

{

Motor_rechts = Motor_rechts - (int)Lenkung_rechts; // Vielleicht auch mit Multiplikation eines Faktors (z.B. * (1 - 0.1) versuchen

Motor_links = Motor_links + (int)Lenkung_rechts; // Vielleicht auch mit Multiplikation eines Faktors (z.B. * (1 + 0.1)) versuchen

}

else // segway fährt gerade rückwärts

{

Motor_rechts = Motor_rechts + (int)Lenkung_rechts; // Vielleicht auch mit Multiplikation eines Faktors (z.B. * (1 + 0.1) versuchen

Motor_links = Motor_links - (int)Lenkung_rechts; // Vielleicht auch mit Multiplikation eines Faktors (z.B. * (1 - 0.1) versuchen

}

Lenkung_rechts = Lenkung_rechts + 0.05; // Besser nur um z.B. 0.1 pro Abfrage erhöhen, damit Lenkung nicht zu abrupt erfolgt!

if (Lenkung_rechts > Lenkung_max) Lenkung_rechts = Lenkung_max; // Maximaler Lenkungswert darf nicht überschritten werden!

//Lenkung_rechts = constrain(Lenkung_rechts, 0, Lenkung_max); // rechter Lenkungswert ins Intervall [0,Lenkung_max] gebracht

}

else

{

Lenkung_rechts = 0.0;

}

Lenkung_Eingang_links = digitalRead(Pin_Lenkung_links); // Abfrage des Pins für Lenkung nach Links

if (Lenkung_Eingang_links == HIGH)

{

// *****************************************

// *** Lenkung nach Links wurde gedrückt ***

// *****************************************

if (Motor_links >= 0) // segway fährt gerade vorwärts oder steht. Welcher Motor abgefragt wird ist egal.

{

Motor_rechts = Motor_rechts + (int)Lenkung_links; // Vielleicht auch mit Multiplikation eines Faktors (z.B. * (1 + 0.1) versuchen

Motor_links = Motor_links - (int)Lenkung_links; // Vielleicht auch mit Multiplikation eines Faktors (z.B. * (1 - 0.1) versuchen

}

else // segway fährt gerade rückwärts

{

Motor_rechts = Motor_rechts - (int)Lenkung_links; // Vielleicht auch mit Multiplikation eines Faktors (z.B. * (1 - 0.1) versuchen

Motor_links = Motor_links + (int)Lenkung_links; // Vielleicht auch mit Multiplikation eines Faktors (z.B. * (1 + 0.1) versuchen

}

Lenkung_links = Lenkung_links + 0.05; // Besser nur um z.B. 0.1 pro Abfrage erhöhen, damit Lenkung nicht zu abrupt erfolgt!

if (Lenkung_links > Lenkung_max) Lenkung_links = Lenkung_max; // Maximaler Lenkungswert darf nicht überschritten werden!

//Lenkung_links = constrain(Lenkung_links, 0, Lenkung_max); // linker Lenkungswert ins Intervall [0,Lenkung_max] gebracht

}

else

{

Lenkung_links = 0.0;

}

// *******************************************************************************************

// ******************************** Ansteuern der Motoren ***********************************

// *******************************************************************************************

Motor_rechts = constrain(Motor_rechts, -127, 127); // rechter Motorenwert ins Intervall [-127,127] gebracht

Motor_links = constrain(Motor_links, -127, 127); // linker Motorenwert ins Intervall [-127,127] gebracht

/*

// Gebrauch einer Wurzelfunktion anstelle der linearen Ansteuerfunktion zur Verbesserung des Ansprechverhaltens bei niedrigen Motorwerten

// ======================================================================================================================================

if (Motor_rechts >= 0) // rechter Motor dreht vorwärts

{

Motor_rechts = sqrt(127 * Motor_rechts); // zur Verbesserung des Ansprechverhaltens bei niedrigen Motorwerten

ST.motor(2, Motor_rechts);

}

else // rechter Motor dreht rückwärts

{

Motor_rechts = -sqrt(127 * -Motor_rechts); // zur Verbesserung des Ansprechverhaltens bei niedrigen Motorwerten

ST.motor(2, Motor_rechts);

}

if (Motor_links >= 0) // linker Motor dreht vorwärts

{

Motor_links = sqrt(127 * Motor_links); // zur Verbesserung des Ansprechverhaltens bei niedrigen Motorwerten

ST.motor(1, Motor_links);

}

else // linker Motor dreht rückwärts

{

Motor_links = -sqrt(127 * -Motor_links); // zur Verbesserung des Ansprechverhaltens bei niedrigen Motorwerten

ST.motor(1, Motor_links);

}

*/

ST.motor(1, Motor_links);

ST.motor(2, Motor_rechts);

}

// ************************************************************************

// *********************** Ausgabe der Messwerte **************************

// ************************************************************************

Werteausgabe();

// ******************************************************************

// *********************** Tastaturabfrage **************************

// ******************************************************************

// Tastatureingabe();

// **********************************************************************

// *********************** loop timing control **************************

// **********************************************************************

LoopTime_Bisher = millis() - LoopTime_Start; // Zeit seit der letzten Schleife

if(LoopTime_Bisher < LoopTime_Soll)

{

delay(LoopTime_Soll - LoopTime_Bisher); // Verzögerung, um die gleiche Schleifenzeit zu erhalten

}

LoopTime_Angepasst = millis() - LoopTime_Start; // aktualisierte Dauer der letzten Schleife, sollte gleich LoopTime_Soll = z.B. 10 msek sein!

LoopTime_Start = millis(); // neue Starteit der Schleife

}

// ********************************************************************************************

// ****************** Werteausgabe an die serielle Schnittstelle ******************************

// ********************************************************************************************

void Werteausgabe()

{

/*

Serial.print(Winkel);

Serial.print(" ");

Serial.println(Motor);

Serial.print(" ");

*/

Serial.print("a_y = ");

Serial.print(ay/16384.0);

Serial.print(" a_z = ");

Serial.print(az/16384.0);

Serial.print(" ACC_angle = ");

Serial.print(ACC_angle,0);

Serial.print(" GYRO_rate = ");

Serial.print(GYRO_rate,0);

Serial.print(" Winkel: ");

Serial.println(Winkel,0);

/*

Serial.print(" Motor: ");

Serial.print(Motor);

Serial.print(" Motor_rechts: ");

Serial.print(Motor_rechts);

Serial.print(" Motor_links: ");

Serial.println(Motor_links);

*/

}

// ******************************************************************************************************

// ***************************************** PID-Steuerung **********************************************

// ******************************************************************************************************

float error;

float last_error = 0;

float pTerm;

float iTerm;

float dTerm;

float integrated_error = 0;

int GUARD_GAIN = 40; // maximal aufintegrierter Winkelfehler

int pid(float Winkel_aktuell, float Winkel_Vorgabe, float Winkelgeschwindigkeit)

{

error = Winkel_Vorgabe - Winkel_aktuell;

pTerm = Kp * error; // Differenzenanteil

integrated_error = integrated_error + error;

iTerm = Ki * constrain(integrated_error, -GUARD_GAIN, GUARD_GAIN); // Integralanteil

dTerm = Kd * Winkelgeschwindigkeit / 100.0; // Differentialanteil; :100 um auf brauchbare Werte zu kommen!

/*

Serial.print(" K_p: ");

Serial.print(pTerm);

Serial.print(" K_d: ");

Serial.println(dTerm);

*/

last_error = error;

// Serial.println(K*(pTerm + iTerm + dTerm));

return constrain(K*(pTerm + iTerm + dTerm), -127, 127); // Ausgabe des Motorwerts für die beiden Motoren innerhalb der Grenzen [-127,127]

}

// ******************************************************************************************************

// ************************************** Kalman filter module ******************************************

// ******************************************************************************************************

float Q_angle = 0.001; // E(alpha2) = 0.001

float Q_gyro = 0.003; // E(bias2) = 0.003

float R_angle = 0.001; // Sz = 0.03 !!! je größer die Zahl, desto unempfindlicher reagiert der Winkel auf Veränderungen !!!

float x_angle = 0;

float x_bias = 0;

float P_00 = 0, P_01 = 0, P_10 = 0, P_11 = 0;

float dt, y, S;

float K_0, K_1;

float kalmanCalculate(float newAngle, float newRate, int looptime)

{

dt = float(looptime)/1000; // dt in Sekunden

x_angle = x_angle + dt * (newRate - x_bias);

P_00 = P_00 - dt * (P_10 + P_01) + Q_angle * dt;

P_01 = P_01 - dt * P_11;

P_10 = P_10 - dt * P_11;

P_11 = P_11 + Q_gyro * dt;

y = newAngle - x_angle;

S = P_00 + R_angle;

K_0 = P_00 / S;

K_1 = P_10 / S;

x_angle += K_0 * y;

x_bias += K_1 * y;

P_00 -= K_0 * P_00;

P_01 -= K_0 * P_01;

P_10 -= K_1 * P_00;

P_11 -= K_1 * P_01;

return x_angle;

}

// ********************************************************************

// ******** Tastaturabfrage zur Veränderung der PUI-Parameter *********

// ********************************************************************

int Tastatureingabe()

{

if(!Serial.available()) return 0;

char param = Serial.read(); // get parameter byte

if(!Serial.available()) return 0;

char cmd = Serial.read(); // get command byte

Serial.flush();

switch (param)

{

case 'p':

if(cmd=='+') Kp++;

if(cmd=='-') Kp--;

break;

case 'i':

if(cmd=='+') Ki += 0.1;

if(cmd=='-') Ki -= 0.1;

break;

case 'd':

if(cmd=='+') Kd++;

if(cmd=='-') Kd--;

break;

case 'k':

if(cmd=='+') K += 0.2;

if(cmd=='-') K -= 0.2;

break;

case 'l':

if(cmd=='+') K_Motor_links += 0.1;

if(cmd=='-') K_Motor_links -= 0.1;

break;

case 'r':

if(cmd=='+') K_Motor_rechts += 0.1;

if(cmd=='-') K_Motor_rechts -= 0.1;

break;

default:

Serial.print("?"); Serial.print(param);

Serial.print(" ?"); Serial.println(cmd);

}

Serial.println();

Serial.print("K:"); Serial.print(K);

Serial.print(" Kp:"); Serial.print(Kp);

Serial.print(" Ki:"); Serial.print(Ki);

Serial.print(" Kd:"); Serial.print(Kd);

Serial.print(" K_Motor_links:"); Serial.print(K_Motor_links);

Serial.print(" K_Motor_rechts:"); Serial.println(K_Motor_rechts);

}